CP-X Method

Prefabricated concrete piles: High bearing capacity, medium excavation, widened foot protection method

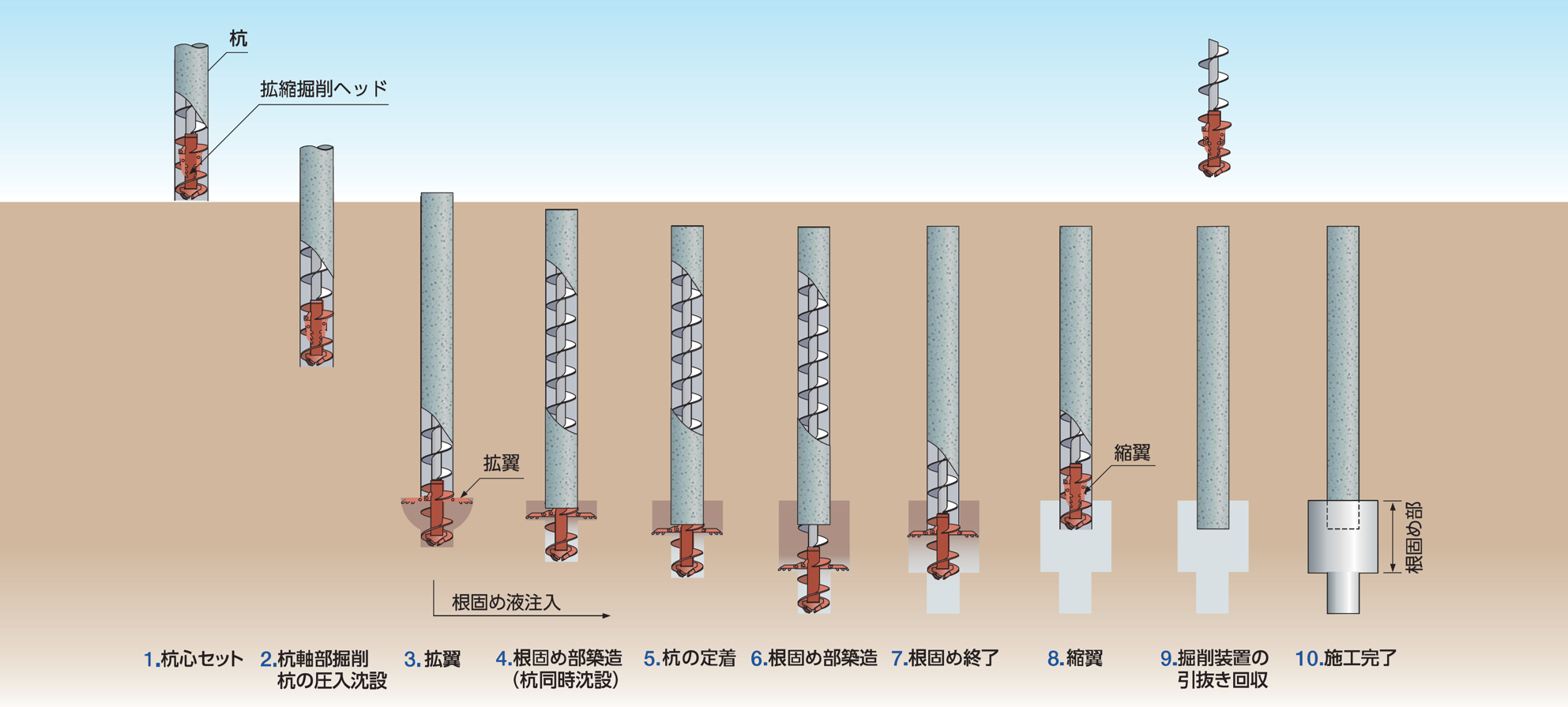

The CP-X method is a precast concrete pile method that has high vertical bearing capacity by constructing a maximum 2,400 mm of base reinforcement bulb at the tip of the pile using a hydraulic expandable drilling head like the TN-X.

It is expected to receive official certification in November 2024 and be adopted for important building structures such as data centers and large logistics warehouses that require high pile bearing capacity.

Feature

Low residual soil volume

By returning the generated surplus soil to the pile holes, the amount of surplus soil generated can be reduced by 65% to 70% compared to pre-boring and cast-in-place pile methods.

This is an environmentally friendly method that limits the amount of surplus soil.

In addition, since no cement is used in any process other than the base reinforcement construction, it can basically be treated as ordinary surplus soil rather than industrial waste. (Conditions must be confirmed)

Effective use of working time

Since pile installation work can be resumed the next day, each working day can be fully utilized.

In response to the recent problem of working hours, we hope to propose a shortened construction period.

High construction precision

By simultaneously burying the piles using the inner excavation method, it is possible to maintain excellent pile center accuracy.

Large end support

By constructing a maximum 2,400 mm root reinforcement bulb at the tip of the pile, a maximum tip bearing capacity of 17,900 kN can be achieved. (Long-term allowable bearing capacity when the tip average N value is 60)

Status of test construction carried out in 2023

Status of test construction carried out in 2023

Construction Method

General building・Special building

Small-scale

Mid-scale

Large-scale

Small-scale building

Civil engineering structures

Small-scale

Large-scale

Liquefaction countermeasures

Vibration control

Construction Method

Piling Method

Soil Improvement Method