NS ECO-PILE MethodRotary pile method

About The NS ECO-PILE Method

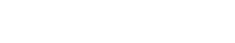

NS ECO-PILE method is a foundation pile method in which rotational press-fitting is used for a steel pipe pile which has a steel plate (blade) that is processed into a spiral shape welded to the tip of the pile. Large-diameter piles are rotationally press-fitted via steel pipes using full rotation pile drivers, while medium- and small-diameter piles are driven by a self-propelled small pile driving machine. Similar to wood screws, the piles are penetrated into the soil via the propulsion of the tip blade.

Features

- An environmentally-friendly method which generates absolutely no waste soil.Since the pile penetrates the soil by rotating the steel pipe without excavating, absolutely no waste soil is generated. This construction method is suitable for conditions where it is necessary to suppress soil discharge, such as when the soil is contaminated.

- High vertical bearing capacity and withdrawal bearing capacity

A large bearing force can be obtained due to compaction of the tip soil caused by rotating press fitting and the bottom expansion effect of the blade. Additionally, the passive applied force that acts as a propulsive force on the blades during penetration then acts as withdrawal resistance. This makes it possible to obtain large withdrawal bearing force.

NS Ecopile Steel Pipe Pile Tip

NS Ecopile Steel Pipe Pile Tip Completely soil-free construction

Completely soil-free construction - Withdrawal and collection is possible.

By rotating the steel pipe in the opposite direction than the time of penetration, the pile can be easily withdrawn and applied as a temporary pile.

The big digging force of the wood screw principle penetrates into the open part of the pile tip in the gravel and cobblestone layer while capturing the digging obstacle.Since it does not disturb the In-situ soil, it exerts the effect of suppressing natural emergence of pressured water.

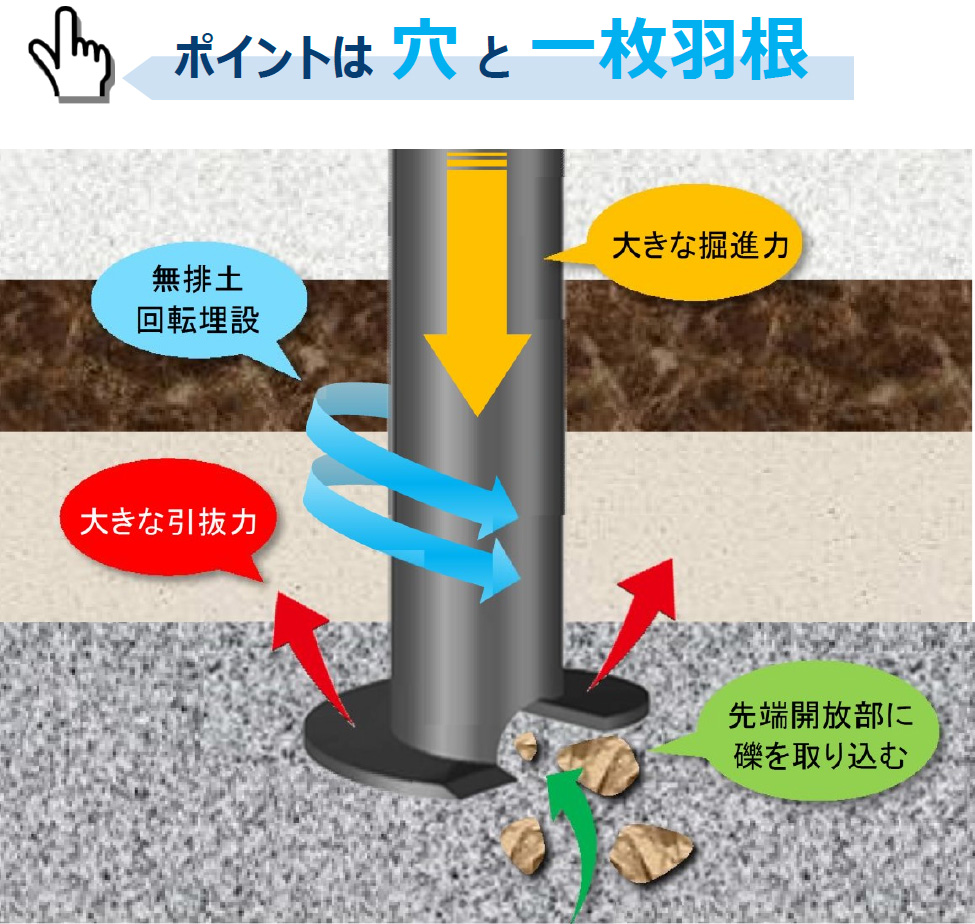

The big digging force of the wood screw principle penetrates into the open part of the pile tip in the gravel and cobblestone layer while capturing the digging obstacle.Since it does not disturb the In-situ soil, it exerts the effect of suppressing natural emergence of pressured water.  If the horizontal force is large or if you want to suppress the horizontal displacement, application of oblique pile is effective.Economical design is possible because the number of piles can be reduced compared to straight piles.

If the horizontal force is large or if you want to suppress the horizontal displacement, application of oblique pile is effective.Economical design is possible because the number of piles can be reduced compared to straight piles. - Offering an extensive lineup of pile diameter and construction equipment.

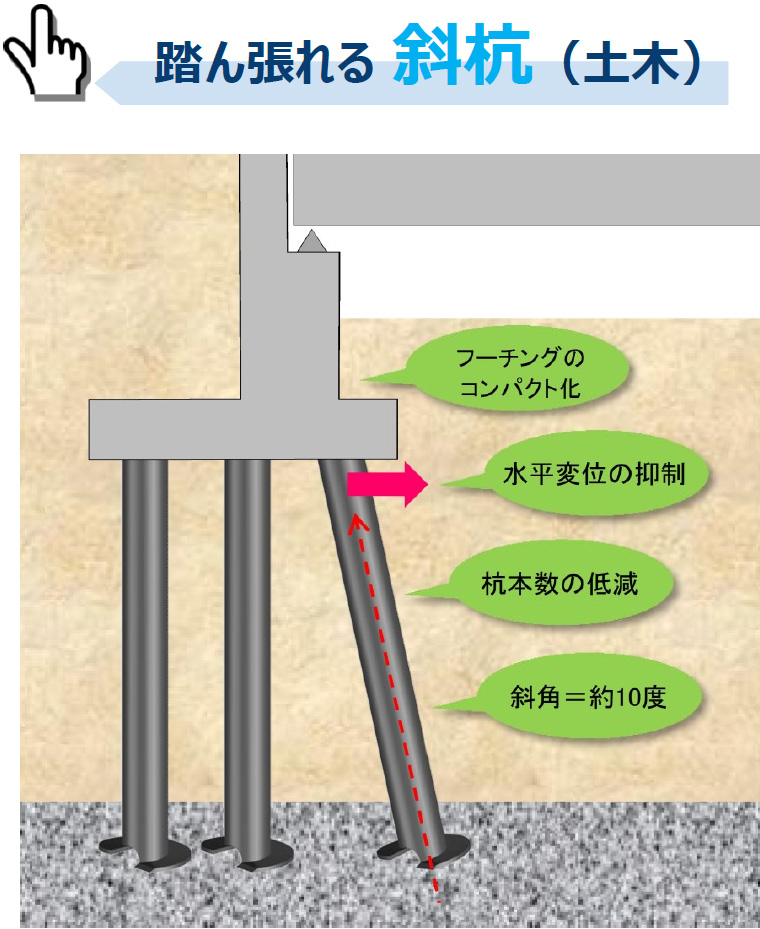

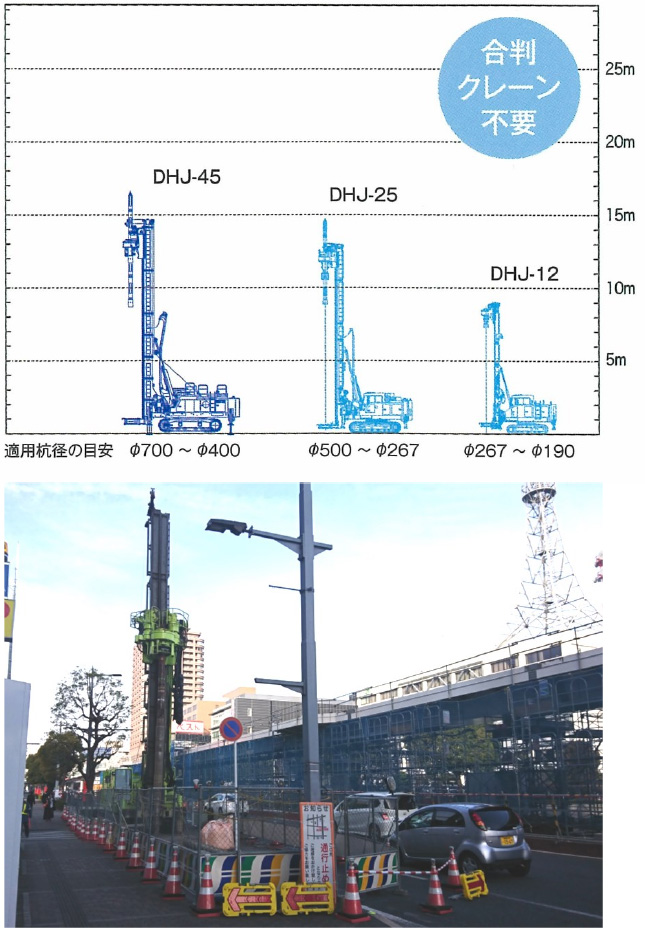

The applicable pile diameter is 400 mm to 1,600 mm in the civil engineering field, and 100 mm to 1,600 mm in the construction field, which enables economical design according to the conditions of the soil and structures. Furthermore, we offer numerous types of construction equipment, ranging from full rotation pile drivers for large diameter piles to self-propelled pile drivers (6 ton class to 45 ton class) for medium and small diameter piles. Users can select the equipment type according to construction conditions.

Middle diameter pile – narrow path pile construction(self-propelled small pile driving machine)

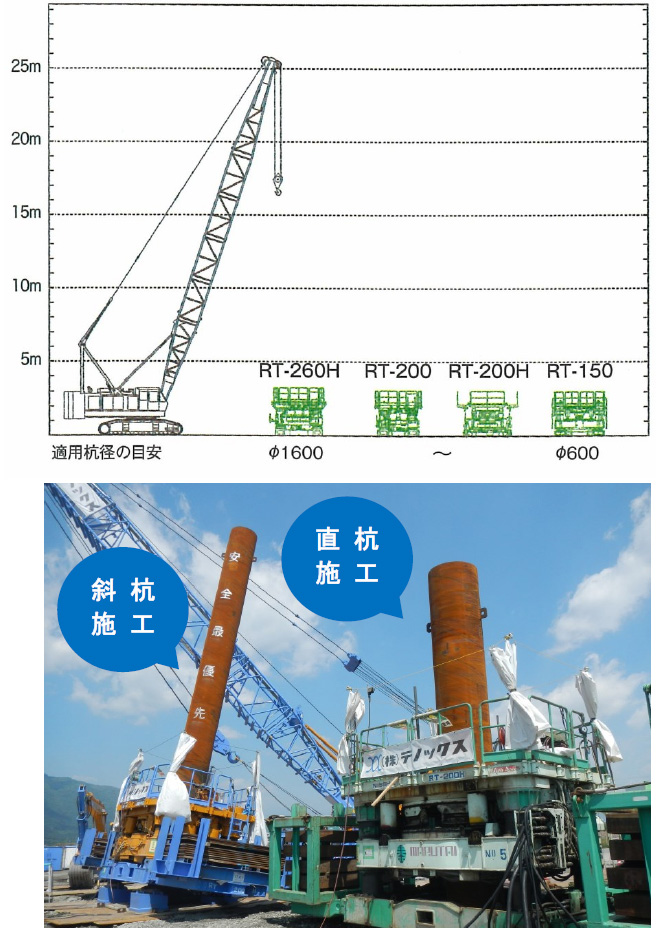

The construction situation of the full rotation pile drivers

The construction situation of the full rotation pile driversMiddle diameter pile – narrow path pile construction(self-propelled small pile driving machine)

The construction situation of the self-propelled small pile driving machine

The construction situation of the self-propelled small pile driving machine

- High applicability in narrow spaces, under height limits, and near structures (medium diameter and small diameter).

Since the pile driver is compact and uses few facilities, it can be used for construction in narrow spaces. Moreover, since no waste soil is discharged during construction, there is no need for a soil disposal yard or a yard for installing plant facilities. This makes compact construction possible. Furthermore, since no waste soil is discharged, it does not loosen the soil around the piles and therefore does not affect nearby structures.

Narrow-mindedness yard construction

Narrow-mindedness yard construction Head limit lower construction

Head limit lower construction Structure proximity construction

Structure proximity construction

Select by load/soil conditions

Building structure

- Detached homes (1 floor to 3 floors)

- Stores/townhouses (2 floors to 3 floors)

- Commercial buildings/residential complexes (4 floors to 5 floors)

- Hospitals/schools (4 floors to 5 floors)

- Factories (4 floors to 5 floors)

- Logistics warehouses (5 floors to 6 floors)

- Mid- and high-rise buildings/condominiums (5 floors to 15 floors)

- Out-of-plane seismic resistance

Civil engineering structures

Select by purpose

Support for buildings

Civil engineering structures

Reinforce earthquake resistance

Prevent soil liquefaction

Reduce environmental load

Prevent landslides

Construction Methods

Pile Method

- TN-X Method

- TN Method

- GANTETSU PILE Method

- NS ECO-PILE Method

- ATT COLUMN Method

- CMJ Method

- EAZET Method

- HiFB Method

Ground improvement method

- TENOCOLUMN Method

- TENOCOLUMN ECO Method

- TOFT Method

- PURE PILE Method

- WIB Method

- BASE BALANCE Method

- CDM-LODIC Method